I’ve recently decided to build a cyclocross frame for the first prototype. I figure if anything’s going to test out the durability of a frame it’ll be a cyclocross race. That and it’s the only sort of bike I don’t own that I’ve always wanted (apart from a recumbent, unicycle, downhill, fixie, penny farthing …).

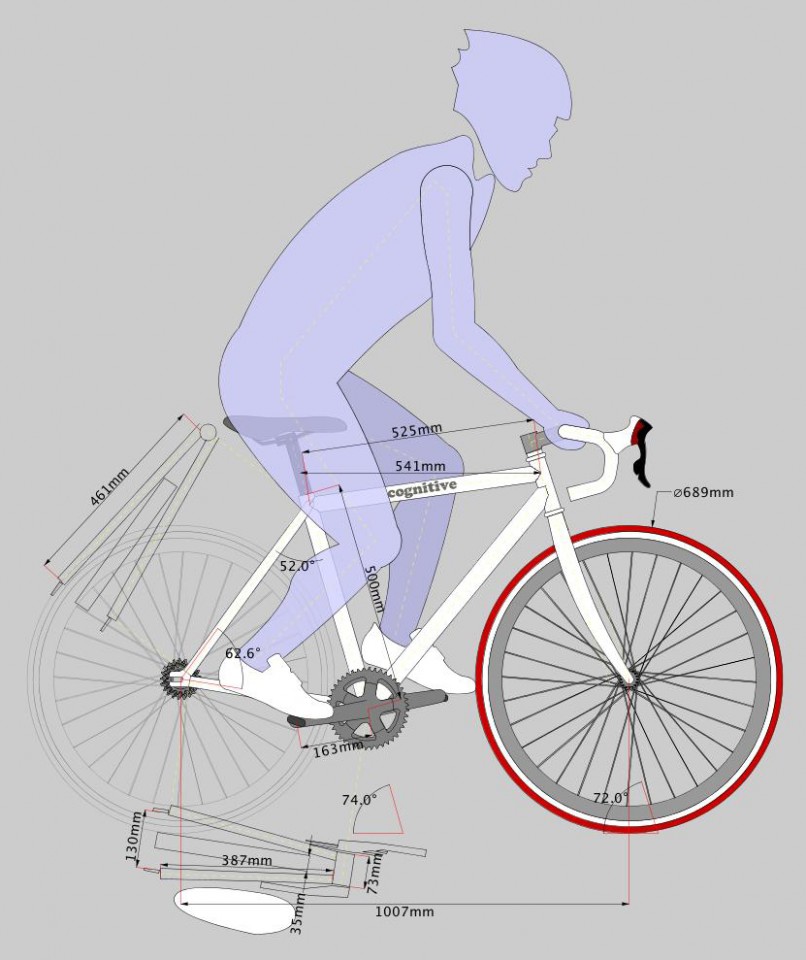

Here’s how it’s looking so far (ignore the colours, I just like designing in red/black/white):

As you can see there’s lots of angles, lengths and diameters to figure out. The BikeCAD above only is only showing the basic frame dimensions and angles, not any of the mitre lengths or tubing diameters.

As you can see there’s lots of angles, lengths and diameters to figure out. The BikeCAD above only is only showing the basic frame dimensions and angles, not any of the mitre lengths or tubing diameters.

The main issue to solve with using bamboo is tyre clearance for the chain and seat stays. I’m picturing that the diameter of this bamboo will be slightly larger than a steel/alu/carbon bike in order to get the greatest stiffness. To help overcome the larger than normal tube diameters I’m using a 73mm bottom bracket as well as a wider than normal seat stay attachment angle. If that doesn’t alleviate the problem I’ll try using skinnier bamboo, but fill it with expanding foam filler, which I’ve been told increases stiffness markedly.

The drop outs, bottom bracket, seat tube sleeve and head tube have all been ordered and are on their way. Soon it’ll be mitre time!